The web Browser you are currently using is unsupported, and some features of this site may not work as intended. Please update to a modern browser such as Chrome, Firefox or Edge to experience all features Michigan.gov has to offer.

Innovative end market uses for compost: Country Oaks Landscape Supply

April 11, 2023

As part of Food Waste Prevention Week, MI Environment is featuring a story from NextCycle, a grantee of the Michigan Department of Environment, Great Lakes, and Energy (EGLE).

Country Oaks Landscape Supply, located outside of Flint, is not your average landscape supply company. As one of only three U.S. Composting Council (USCC) Seal of Testing Assurance (STA) certified compost producers in the state of Michigan, their core business is producing certified compost. But they do not stop there. Country Oaks is constantly looking to employ innovation to capture efficiencies in compost production, while creating new blends, applications, and end markets for their products.

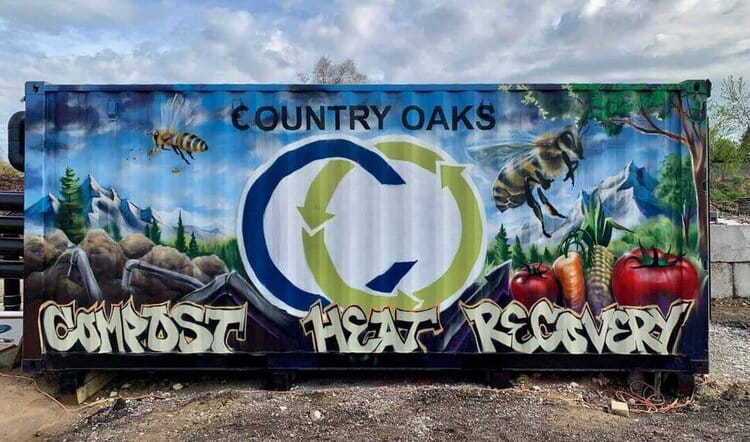

Country Oaks' compost heat recovery hot box.

The challenge

In order to keep opportunities and doors open during the pandemic and continue diverting organics form the landfill, Country Oaks had to find ways to optimize their systems to reduce ongoing marginal costs, while simultaneously uncovering new revenue streams. This would require innovation, partnership, and dedication to continuously evolve the company’s capabilities.

The solution

Country Oaks was able to employ innovation and partnership in several ways.

They continued producing STA-certified compost and incorporating it into new soil blends. The success of this core product offering, and related spin offs, highlights the viability of compost end-use markets supported by high-demand for quality products. Matching their supply to meet demand is key to a successful composting operation and for keeping the industry strong.

Country Oaks optimized their production system to capture and recycle valuable energy and carbon dioxide (CO2) generated through the process. The compost operations include aerated static piles (ASP) technology with a compost aeration and heat recovery (CAHR) system designed by Agrilab Technologies. The system allows Country Oaks to heat their buildings with the thermal energy generated through the compost process. The system also mitigates odor issues from processing organic materials. They recently built a hoophouse for an aquaponics project using the heat captured with the CAHR System and plan to also use the CO2 coming from the compost biofilter. While there is an up-front costs associated with this system, over time, it will reduce ongoing operating costs.

Country Oaks manufactures compost and filter media for use in compost socks. This alternative product line is a sustainable solution for erosion control that prevents sediment and pollutant run-off. They have invested in the technology and equipment to custom bag, fill, and produce compost socks for shoreline retention and low impact development controls.

Country Oaks' compost operation.

The team

Country Oaks worked with partner Agrilab Technologies Inc., to integrate and customize the CAHR system to their process.

They also partnered with Green Horizons Environmental as a channel partner for utilizing the compost socks in shoreline retention solutions. When this fertile green infrastructure is seeded with a nursery crop and deployed along damaged shorelines it quickly grows and locks the system together.

The results

By continuing to innovate, engage in valuable partnerships, and build upon a solid core business line, Country Oaks reveals a pathway to create a profitable privately owned organics business producing high quality compost, contributing to a circular economy, with satisfied customers. It is a true success story in the Michigan composting industry with lessons for other aspiring organics entrepreneurs to learn from.